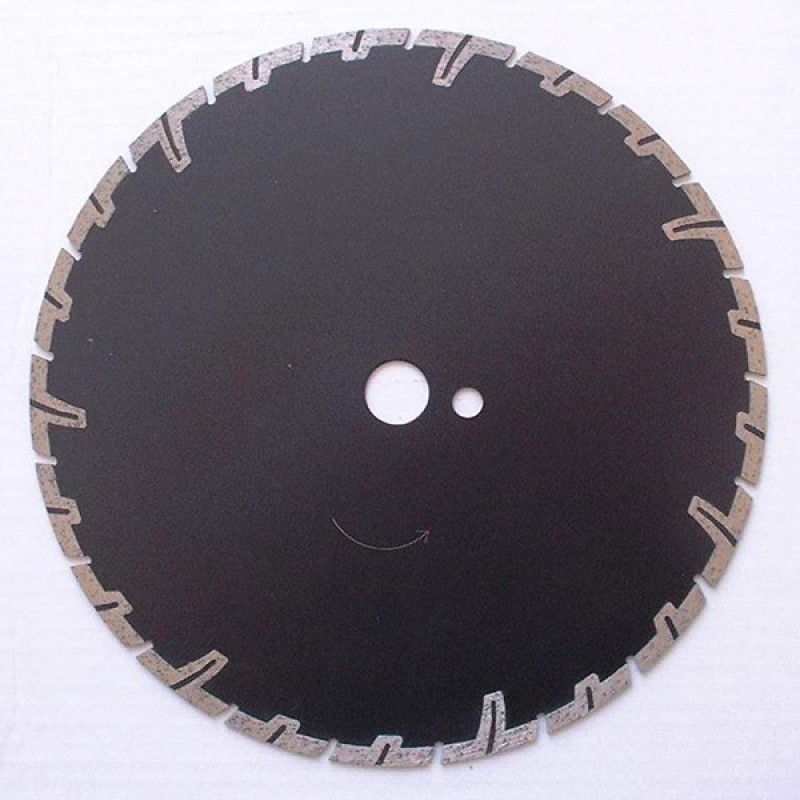

The Diamond blades are produced by Hot press sintered which provide the diamond blades in similar performance as laser weld diamond blades, but keep the price lower than laser weld blades. As the blades are designed with undercut protective segmented in T type that provide the blades can not only fast cut hard materials but also can cut a widely range of abrasive materials and also in long working life. This is a very ideal general propose blades for universal applied.

There are some designs of the bond & diamond grit composition on the segments to meet different specific materials cutting.

Segments in the 2C-composition of the bond & diamond grit, the blades are recommended to cut General Building Materials, Hard to Medium Hard Concrete, Hard to Medium Hard Granite, Clay Brick & Block, Green Quartz Concrete.

Segments in the 3A-composition of the bond & diamond grit, the blades are recommended to cut Soft & Abrasives Materials, Sand Stone, Refractory. General Green Concrete, Series Soft & Abrasives Brick/Block/stones.

Segments in the GP-composition of the bond & diamond grit, the blades are recommended to cut Facing Brick, Refractory, Ceramic, Clay Tiles & Pipes, Concrete Roof Tiles, Engineering Brick & Block, Concrete, All Stones, Granite, Marble, Slate, Terrazzo, and Very Wide range of building materials, etc…

REMARK: Other Specifications & Sizes are available upon request. Bond & Diamond is adjustable upon request to cut specific materials.

Suitable: Dry cutting.